As individuals we come up with really good ideas, changes to Products, Processes, and/or People in order to drive higher levels of Performance. If we find a few people who think like us, the ideas and plans can become very elaborate. We can hide in our offices or in the Innovation Stations and draw thought maps that would rival the great thinkers of Harvard and Yale. But when we start implementing we fail to see the change we were looking for, our great ideas are stoned in the middle of the street, and we are ridiculed in front of our peers.

And that did not turn out how we thought it would.... once again.

Shaping the Vision

As we have explored before,

change is hard. It's harder when we don't include decision makers and smart people in the deployment of the vision. The Captain of the ship points the way and we get to figure out how to get there. "We" does not mean only the Directors and Senior Managers, it means all of us. There are oodles of people out there, with skills and abilities that can help plan the change, execute the plan, transform the organization, and assess the results.

As the Captain's Executive Officer (XO), you get to figure out how to take the sometimes lofty statements by the boss and then translate them into what the future looks like for the organization and you are the point person for supporting the teams when the transformation begins. More than likely you have something to start with, the Vision & Mission Statements, and the boss's lofty statements will typically track along in parallel. Functionally this means something slightly different for each section of the organization based on how each connects to the main product or service that is provided.

|

| The Correct Way To Draw An Org Chart |

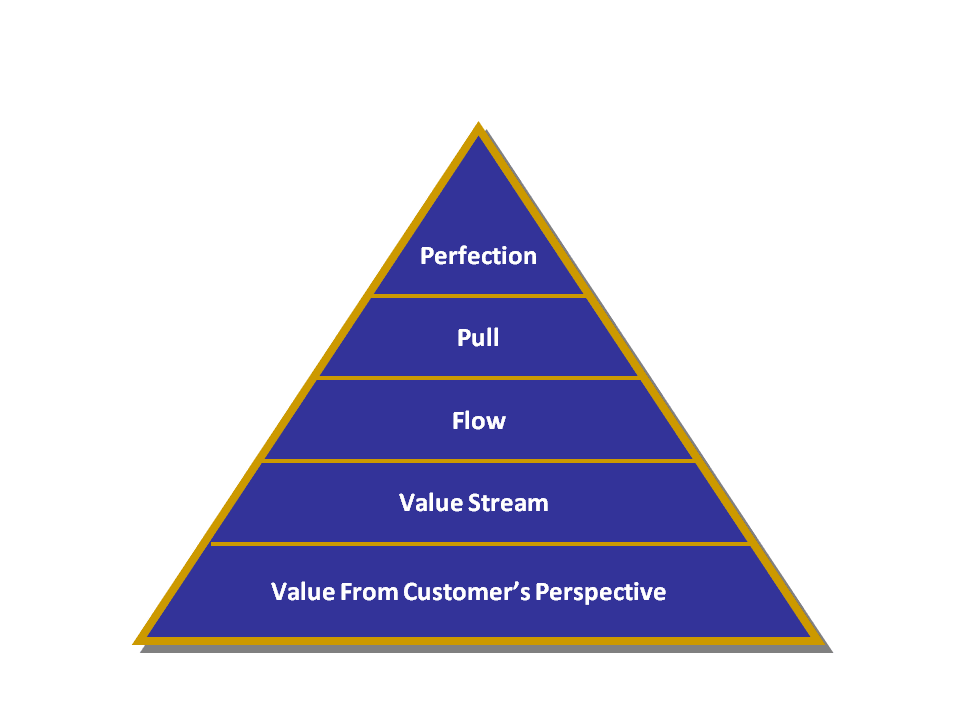

We have discussed

creating the vision and

specifying value in the past, but how do we take our thoughts and dreams on paper to those in the organization that will be going on this journey with us? Spend some time talking with those teams to explore how they see themselves fitting into the Vision & Mission Statements and what do their metrics say about performance. When they talk about the "things" they provide for the product or service, are they reflected on your VSM or Strategy Map?

Communicating the Vision

I'm going to presume that if you are in some sort (any sort) of Leadership position, that you have gotten over the fear of public speaking. This will not be a one-time flash of the power point slide during an all-hands meeting and then you never speak of it again. It will be discussed until everyone understands and are ready to start moving forward, and part of the conversation will be one where the vision is shaped.

You should discuss it everywhere you go. Visit all the teams in their stand-up meetings, even if it's at 6am. If you can put it on one piece of paper, hang the vision in the break rooms and the performance measurement screens on the walls. Make it part of the company newsletters and create a video discussing the vision and how important it is to the organization. When you are discussing it, do try to sound a little excited about the journey and the possibilities it will open for everyone. And let the teams know they are part of this journey because they will be making adjustments to their 4P's also.

Share results with the organization while the transformation is ongoing. What are the wins, what are the lessons learned, and what has been accomplished? Reward some team members if you are having an all-hands meeting with the organization. Instant awards like restaurant gift cards are cheap and easy. Handwritten thank you notes provide a personal touch not seen today as often. Award certifications if there are Green Belt or Black Belt certification projects tied to the change.

People want to know what you think about the transformation and if they are doing a good job. Communication always comes up as a top issue for organizations and some of these ideas can help move you forward along your Lean Transformation.